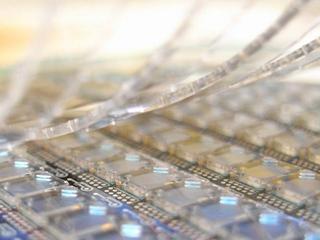

Biosensor Quality and Technology

Technology

- biosensor fabrication under quality management system

- reference and counter electrode on chip

- up to 12 modified platinum electrodes as electro-chemical transducers

- redundant biosensors maximize analytical reliability

- photo-patternable nano-composite membranes

- simultaneous measurement of glucose, lactate, glutamine, glutamate and pyruvate

- activity optimum at physiological dynamic range, neutral pH

- for in vivo and ex vivo applications in whole blood and fermentation broth

- internal volumes 0.15 — 0.4 µl

- flow rates used range from 0.1 to 100 µl/min

- array stability of typically at least one week at continuous operation

- flow rate sensor on chip

- rugged low volume fluid connection

- micro flow-system with nanoliter internal volume

- all plastics flexible mass producible devices

- traceability by unique bar code label

- Optional aspiration line (110 µm o.d. stainless steel tube)

- Optional integrated static mixers allow online dilution

- Laminate technology for flexible and customized devices

Quality

- ISO 9001 certified quality system

- production fully documented

- 100% QA functionality testing

- 100% device calibration

- unsurpassed accuracy in calibration free use — compared to batch calibration

- Tracking of individual devices by 2D bar code